What Size Kreg Screw For 1/2 Plywood

Choosing a Screw

Kreg Screws are bachelor in several dissimilar types, each with unique qualities that optimize performance in specific applications. Once you understand these qualities, information technology's easy to choose the right Kreg Screw. In this video, nosotros have a few minutes to tell yous most each type of screw, and we advise a few unproblematic guidelines you should consider to choice the all-time screw for everything y'all build.

Kreg Screw Qualities

Composition:

Steel Kreg Screws are case hardened — a process that forms a tough outer beat out (or case) to make the spiral durable, just keeps the core softer to preclude the screw from becoming brittle. That means y'all get the best of both worlds: a strong screw that won't snap. Kreg Screws are available in three finishes.

Zinc-coated screws are recommended for a wide variety of indoor projects where moisture is non a concern.

Blueish-Kote™ screws are the all-time choice for damp or wet applications. They feature three anti-corrosion layers, making them perfect for outdoor use and loftier-moisture environments.

Stainless steel Kreg Screws are designed for employ in extreme applications, excessive exposure to salt water, and other exceedingly corrosive environments, such as fastening ACQ-treated lumber.

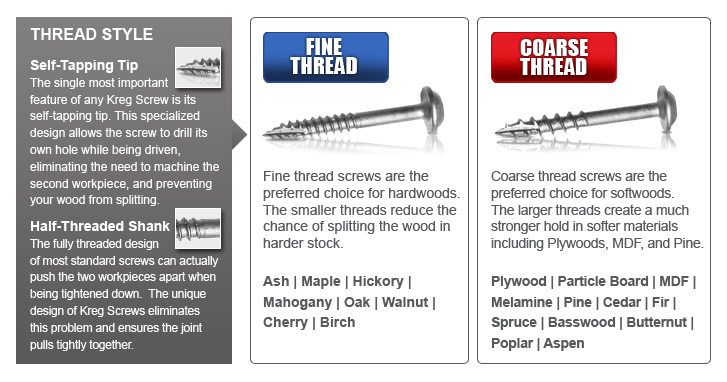

Thread Style:

Coarse-Thread screws are recommended for utilize with softwoods similar cedar, pine, fir, etc. — as well as for sail goods such as plywood and MDF – that are soft and not very dumbo. Coarse screws take deep, aggressive threads that bite into those soft fibers to ensure solid holding power.

Fine-Thread screws are the preferred choice for hardwoods like cherry, maple, oak, etc. that are hard and dumbo. Fine threads are less aggressive, and so they'll bulldoze without splitting, but these screws have a higher number of threads per inch to ensure great holding power.

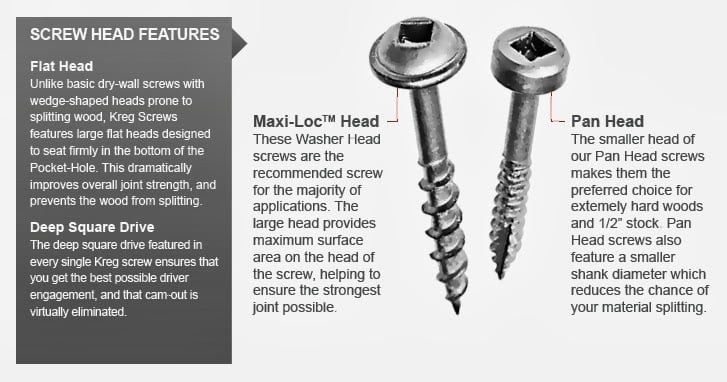

Head Style:

Ordinary woodworking screws and drywall screws have a caput with a conical shape on the underside. The caput on a Kreg Screw is perfectly flat on the underside to mates perfectly with the flat lesser in a Kreg pocket pigsty. When you drive a Kreg Screw into the pocket hole, this flat shape applies strength direct toward the spiral tip, so it holds the joint tightly together without deforming the pocket, which could divide the wood. Kreg Screws are available in two head styles.

Maxi-Loc screws are a neat choice for the majority of applications. These Kreg Screws have a large head that provides maximum bearing surface as the screw pulls tight in the pocket.

Pan-Head screws are perfect for dense hardwoods and for 1/2″ thick stock. Their smaller shank reduces the chance of splitting, and the smaller head allows them to fit places where space is limited and/or tight pocket-hole spacing is desired.

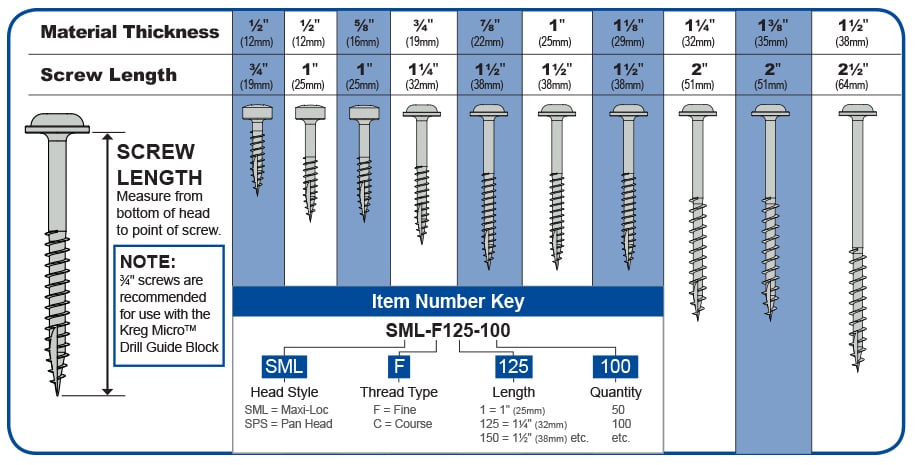

Screw Length

Selecting the correct screw length is the most important consideration when choosing a Kreg Screw. We suggest using the screw lengths shown beneath when joining materials of the same thickness (such every bit joining three/4″ thick cloth to 3/4″ thick material). To help select the correct spiral length when joining materials of unlike thicknesses, our Spiral Selector Cycle is a handy tool.

The threads on a Kreg Screw stop partway up the screw shank, which leaves a smooth area beneath the screw head. When the spiral is driven in, the threaded portion grabs into the workpiece you're attaching to, pulling the spiral in. The other piece glides freely over the unthreaded role of the screw, assuasive that piece to pull tightly confronting the mating slice — without unnecessary threads that can actually push button the joint apart.

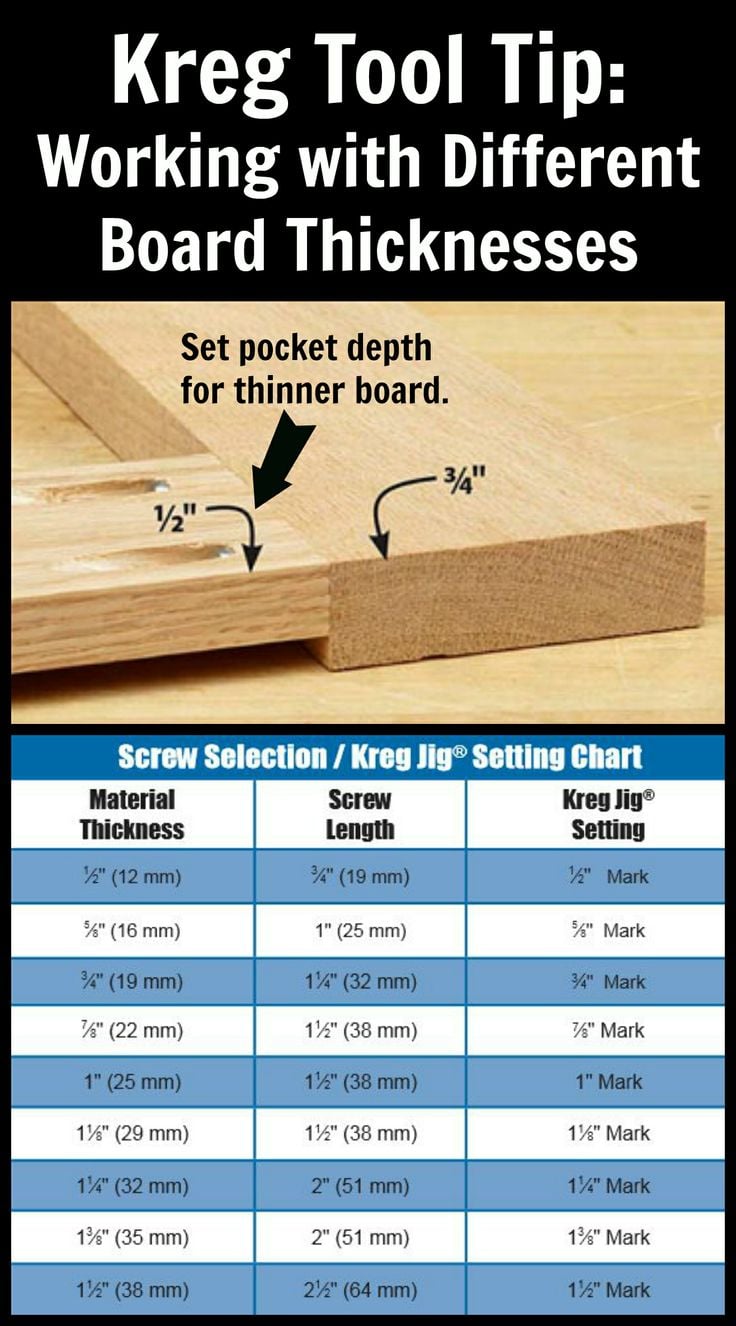

Working with Different Board Thicknesses.

Kreg Tool Tip: Working with Dissimilar Board Thicknesses | When joining boards of two different thicknesses edge-to-edge or end-to-edge, gear up your Kreg Jig® according to the thickness of the thinner board. The flick shows a ½"-thick lath and ¾"-thick board that were joined with pocket holes. As yous can see, the Kreg Jig® was gear up for ½"-thick material, the thinner board. We've also included a helpful chart that shows which Kreg Jig® setting and screw length to use based on material thickness.

Why should I use Kreg Screws?

Frequently Asked Question:

Question: Can I use whatever screw?

Answer:

I wouldn't use any other screw than a Kreg. The price difference is relatively small, and their screws are far superior.

- Cocky-tapping tip reduces chances for splitting.

- Deep square drive never strips out.

- Very difficult steel; i've never had i break off in the hole (the frustration from having this happen even once with some other spiral will have you thinking as I do well-nigh immediately).

- They have a screw for everything.

- Threads but go up one/two the screw, this prevents the screw from pushing the two workpieces apart.

(Maybe the most important) Kreg screws have a flat bottom head which creates a solid joint and prevents splitting. This is a major difference Kreg has over many others. - They are designed to be the best option for pocket joints. You may exist able to go to a hardware shop and buy like screws at a amend price, only exist sure they have cocky-tapping threads.

Video: Choosing The Correct Kreg Spiral.

Video: Your Kreg Projects Demand Kreg Screws.

What Size Kreg Screw For 1/2 Plywood,

Source: https://wood.tools4.co.za/blog/choosing-the-correct-kreg-screw/

Posted by: plattbefoom.blogspot.com

0 Response to "What Size Kreg Screw For 1/2 Plywood"

Post a Comment